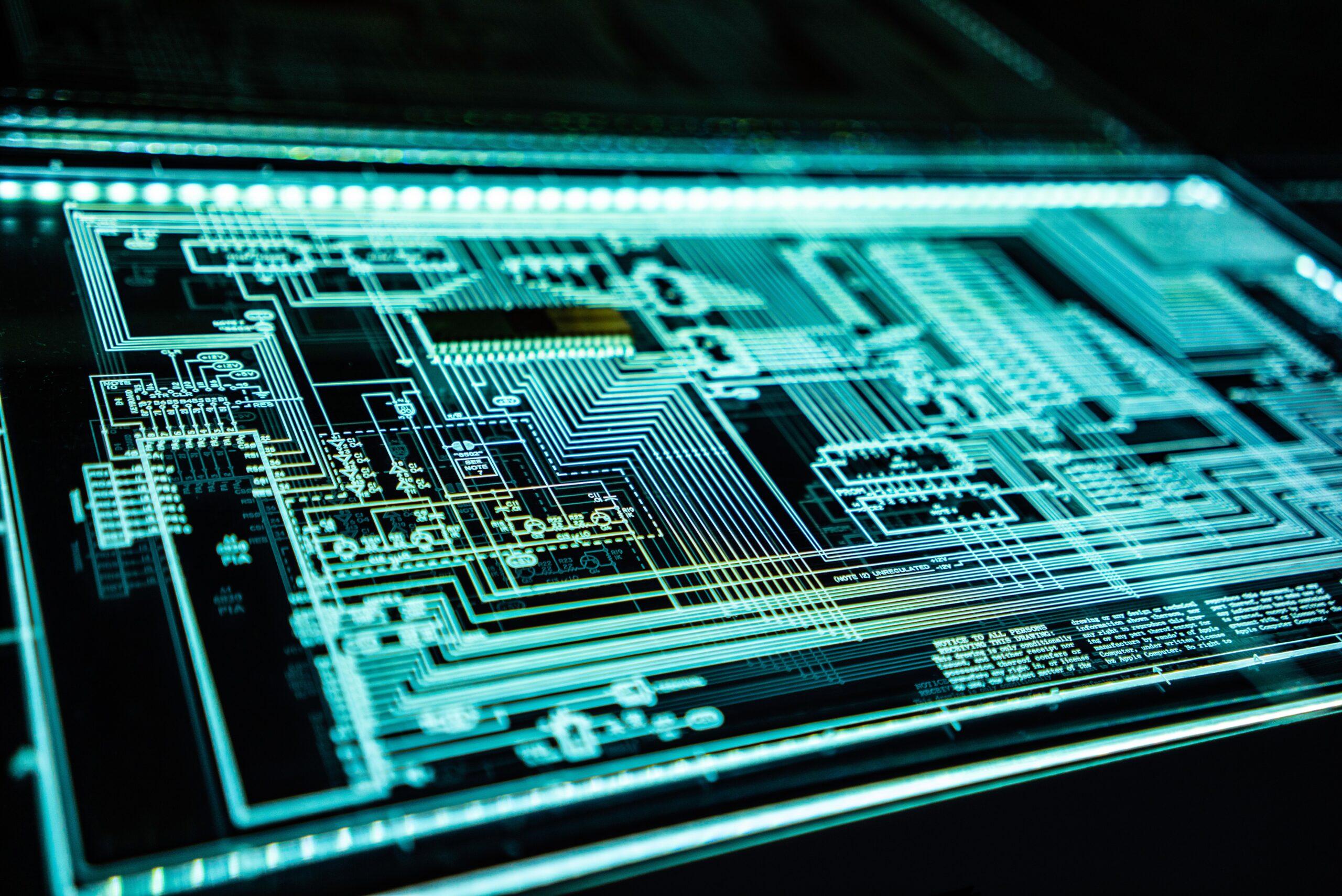

Over 20 years of experiences in EMS business, we are passionate in providing the best services to customer with high-quality PCBA, software installation, Box-build, New Product Introduction (NPI) and product testing for key markets including air-condition, kiosk machines, set-top boxes, car audios, data storage device (HDD) and telecommunication.

Our strong R&D team keeps up with the technology trend and together with our EMS team, both work to ensure the optimize solution of high precision and quality product to fulfill our customer satisfaction.

Due to modular production line, Forth EMS is capable in NPI in which leading the pilot run, test run and mass run production on full assembly process starting from PCBA to Box-build. The high mixed products can be served through flexibility line layout and modular production. Due to fast moving in world-wide, we believe that our flexibility and adaptability will enhance the services to customers in cost effective way. Whether you need the most flexible services or high mass production, Forth EMS capable of serving you.

In addition, the re-invested earning do not end up in only advance machinery technology, but also in Human Resource and IT system to keep up with the world standard. For instance, our latest ERP and MRP tools are SAP system which we implemented for sale, production and material management.

Our mission is to provide customer satisfaction, best price point, quality, services and long term relationship with wide range products and order quantity support both NPI and mass production.

Manufacturing capacity

- HIGH TECHNOLOGY 16 SMT LINES AND 6 AI MACHINES; ON AVERAGE 250 MILLION PARTS PER MONTH

- 3 AUTO WAVE SOLDERING 4,500 STANDARD BOARD PER DAY

- 1 SELECTIVE SOLDERING 1,500 STANDARD BOARD PER DAY

- 6 FINAL ASSEMBLY 2,000-5,000 COMPLETE SETS PER DAY

- BUILD-TO-ORDER /CONFIGURE-TO-ORDER (BTO/CTO)

- NEW PRODUCT INTRODUCTION (NPI)

- HIGH-MIX, LOW-VOLUME/LOW-MIX, HIGH-VOLUME

- WIDE RANGE PCBA CAPABILITY

- NO-CLEAN PROCESSES WITH NITROGEN [N2] SOLDERING

- PRESS-FIT

- SURFACE MOUNT TECHNOLOGY (SMT) AND AUTO INSERTION (AI)

- THROUGH HOLE ASSEMBLY

- FINAL ASSEMBLY

- LEAD FREE (PB FREE, ROHS)

- 0603 CHIP, MICRO BGA AND ALL SMD

- TRACEABILITY SYSTEM

Testing and Inspection Capability

- X-RAY [2D,3D]

- SPI [3D] AND AOI [2D,3D, IN-LINE AND DESK TOP]

- ICT AND FCT

- BURN-IN CHAMBERS, SHOCK TEMP TEST

- POWER BURNING

- FULL INSPECTION SYSTEM: IQC, IPQC, OQC

- FA EQUIPMENT SUPPORT AND BGA REWORK STATION

- DRY AND PIY AND CROSS SECTION

- TEST SYSTEM DEVELOPMENT

Ready to provide contract manufacturing and assembling electronic products.

For More Information, Please Contact

Forth EMS Public Company Limited

77 Moo 11 Phuttamonthon 5 Rd., Rai Khing, Sampran, Nakhon Pathom 73210

Tel: 02 420 2888 Email: sale@forthems.co.th